Calibration Wafer Standards,

Cleanroom Smoke Studies,

Airflow Visualization Foggers,

Silica Microspheres,

Polystyrene Microspheres,

Particle Size Standards

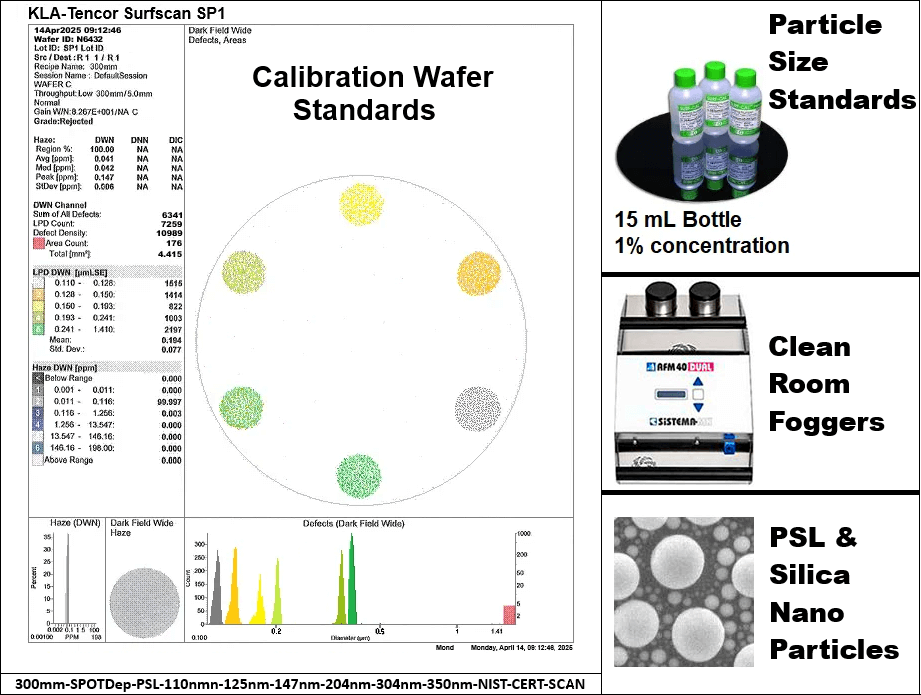

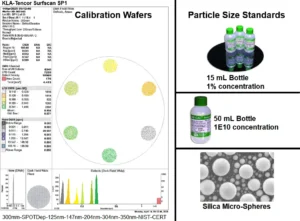

PSL Calibration Wafer Standards are produced for calibration of KLA-Tencor, Hitachi, etc. wafer inspection machines, referred to as SSIS tools. Polystyrene microspheres are deposited from 30 nm up to 15 µm on the surface of 300mm, 200mm, 150mm, 125mm, 100mm and 75mm wafers; as well as customer quartz masks and customer film deposited wafers. These standards are referred to by Metrology Engineers as Particle Size Standards, Wafer Standards, PSL Wafer Standards and Wafer Calibration Standards, etc. Particle Size Standards are deposited on prime silica wafer substrates, customer’s film deposited wafers and customer’s mask substates and used to calibrate the size accuracy and size response of your Tencor, KLA, KLA-Tencor, Hitachi, TopCon, Applied Materials, Tokyo Electron wafer inspection systems and SSIS scanning systems. Circle Depositions called SPOT Depositions on a single wafer standard is provided, as well as Full Depositions or Half Depositions on single or multiple wafers.

Our 300mm Prime Silica substrates are typically clean down to 18nm, while 200mm prime silica substrates are typically surface cleaned to about 80nm. Our 300mm and 200mm silica wafers start out quite clean, allowing for a number of particle size depositions on a single wafer. Multiple particle depositions, Circle and SPOT Depositions, on a single wafer have the advantage of enabling your wafer inspection system, commonly called a scanning surface inspection system or SSIS, to be verified for calibration accuracy across a broad range of sizes during a single wafer scan. On the other hand, FULL Deposition wafer standards provide a single particle size calibration during a wafer scan, while allowing the Metrology Engineer to observe how uniform the particle detection is across the entire surface of a uniformly deposited, Full Deposition Wafer Standard.

Our Smoke Studies Foggers, also referred to as smoke generators and smoke machines, are used in Pharmaceutical and Semiconductor clean rooms and ISO suites to verify airflow uniformity in the clean room, around equipment and from ISO Suite to ISO Suite. Smoke Studies and Airflow Visualization Studies are mandated in the Semiconductor industry using USP797 guideline, SEMI Standards guidelines or ISO guidelines. The pharmaceutical industry is controlled by USP 797 and FDA guidelines in most smoke studies. We provide ultrasonic foggers and LN2 Foggers for Smoke Studies, using 80mm fog outlet or 80mm dual fog outlets, combined with fog velocity control and fog volume control with controlled fog output to visualize airflow turbulence and dead airflow zones in cleanrooms, bio-safety cabinets, airflow hoods, barrier isolators, etc.

Our stainless steel foggers are designed with brushed stainless steel, 80mm fog outlets, fog velocity and fog volume control; and also has optional wireless remote control along with 11 different fog attachment accessories for smoke studies in clean rooms, ISO suites, sterile rooms, Barrier Isolators, etc. Our Apollo 35, Apollo 50, Apollo 100 and Apollo 150 use liquid nitrogen and pure water (De-Ionized, WFI or Sterile) to produce a very dense, ultrapure, adjustable fog volume providing a superb airflow visualization with a paper-white fog. The technology of the nitrogen foggers is unmatched by any other fog generating technology used in clean rooms, ISO Suites, Sterile Rooms, Barrier Isolators, etc. Liquid Nitrogen foggers produce far more fog than ultrasonic transducers, CO2 (dry ice) or glycol fluid/hot wire technology. The Apollo 35 and Apollo 50 nitrogen-di-water fog machines are our standard LN2 foggers with 1 80mm fog outlet, while the Apollo 100 has two 80mm fog outlets and Apollo 150 has three 80mm fog outlets to reduce the amount of time needed to conduct a complete smoke study. Our nitrogen foggers are used for contamination free, smoke studies, air flow visualization and mapping studies in clean rooms, sterile rooms, medical surgery rooms, ISO suites, etc., according to ISO 14644-3 annex b7, or ISO 14644-2 guidelines.

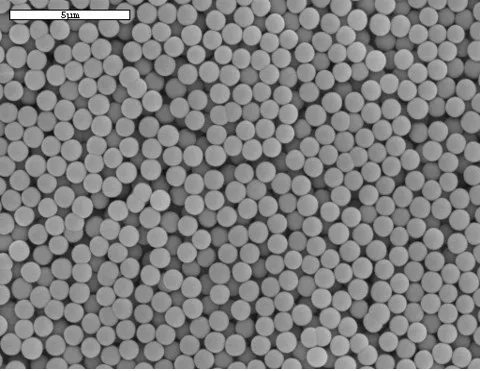

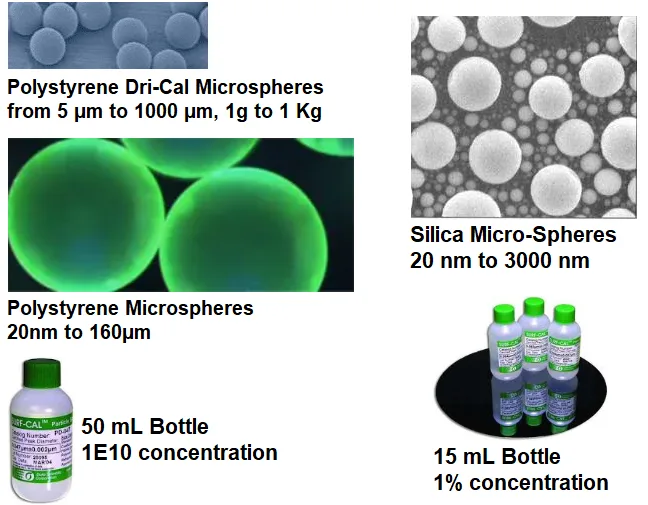

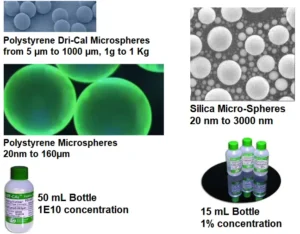

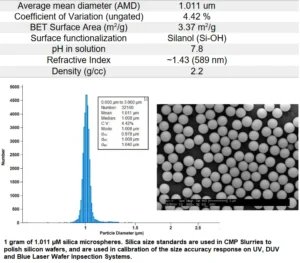

Particle Size Standards are highly accurate size standards typically used to calibrate aerosol particle counters for size accuracy. Polystyrene microspheres are available from 20 nm to 1000 µm; while our Silica micro-spheres are provided from 30 nm to 1 µm (1000nm). Both types of particle size standards are used in aerosol research, particle counter size calibration and Pharmaceutical drug delivery. Silica micro-spheres are especially beneficial in Semiconductor CMP Slurry to provide the surface polish of 300 mm and 200 mm silicon wafers.

PSL Wafer Standards used for SSIS Size Calibration

Our Wafer Calibration Standards are used in Semiconductor Metrology Clean Rooms to calibrate the size accuracy and scanning uniformity response of Wafer Inspection Systems and Scanning Surface Inspection Systems (SSIS) using highly accurate, NIST Traceable, particle size standards with narrow size distributions.

Polystyrene Microspheres, NIST Traceable Sizing, Narrow Size Distributions

Our Polystyrene latex micro-sphere, particle size standards provide exceptional size accuracy and narrow size distribution for use and in Aerosol Particle Research, as well as in deposition of Calibration Wafer Standards.

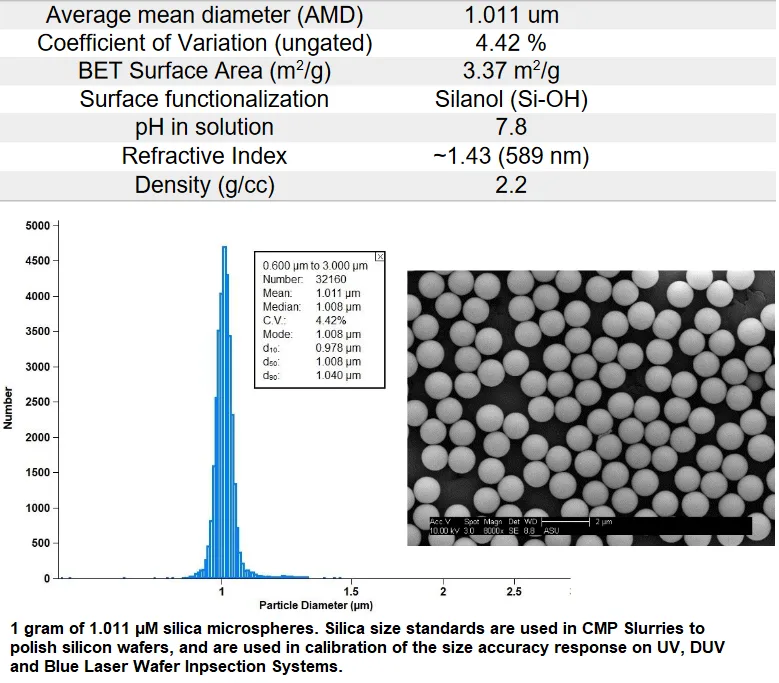

Silica Microspheres for Semiconductor Metrology, CMP Slurry & Pharmaceutical Drug Delivery

NIST Traceable, Silica Microsphere, particle size standards are provided for size calibration of high power UV, DUV & blue laser wafer inspection systems. Silica particle size standards are also used in Drug Delivery and in CMP Slurries at 300 nm, 500 nm and 800 nm.

Smoke Studies Fogger for Airflow Visualization Studies, USP 797

Our Nitrogen-DI-Water Smoke Study Machines and Ultrasonic Smoke Studies Foggers are used in Airflow Visualization Studies of Pharmaceutical process labs, ISO Suites and Semiconductor Clean Rooms to visualize air flow, turbulence, patterns, uniformity and to locate dead zones around equipment and under doorway entrances.

About Cleanroom Metrology LLC

Cleanroom Metrology LLC is at the forefront of Particle Deposition by providing PSL Wafer Standards for Calibration of SSIS tools using Silica microsphere and Polystyrene particle size standards and beads. Our Silica and Polystyrene beads are used as Particle Size Standards around the world in aerosol research. Our Smoke Studies Fogger support USP 797 Guidelines for airflow visualization studies and FDA smoke studies of clean rooms, ISO suites and process labs around the world.

Our PSL Wafer Standards produced as a Full Deposition, Half Deposition, Spot Deposition and Circle Deposition calibration wafer standards are produced to support Semi Standards M52 guidelines for contamination control and size calibration of Scanning Surface Inspection Systems and SSIS tools by providing NIST Traceable, particle size accuracy in the size calibration of SSIS tools, such as KLA-Tencor SP1 TBI, SP2, SP2XP, SP5 un-patterned wafer inspection systems, as well as KLA patterned wafer defect inspection systems. We focus on product quality, product performance and particle size standards.

Our Precision-Engineered Metrology Products

PSL & Silica Wafer Standards

Engineered to the highest specifications, our silica wafer standards are deposited with NIST Traceable particle size standards on ultra-clean silica wafers, which are essential for maintaining size and calibration accuracy of unpatterned Wafer Inspection Systems and pattern defect Surface Scanning Inspection Systems around the world.

Polystyrene Latex Beads

3000 Series and 4000 Series polystyrene latex beads are micro-sphere particle size standards produced from 20 nanometers to 1000 microns, typically in a 15 mm bottle, with 1% or less concentration in De-Ionized water solution. Dry Beads are also available in 1 g, 5 g and up to 1 kg volume. Our Micro-spheres and dry beads are known worldwide for NIST Traceability, size accuracy and narrow size distribution used in a wide range of contamination control and aerosol science applications.

Silica Micro-Spheres

We offer silica micro-sphere, particle size standards, typically used in the deposition of Contamination Calibration Wafer Standards. Silica particles are also used in drug delivery systems to transport, protect, and release drugs in a controlled manner in human and animal applications. Silica nano-particles are especially beneficial in CMP Slurry applications of surface polish of 150mm, 200mm and 300mm silicon wafers.

About Cleanroom Metrology LLC

At Cleanroom Metrology LLC, our unwavering commitment to innovation, quality, and customer support is the cornerstone of our success. We continuously push the boundaries of technology to develop cutting-edge contamination wafer standards and Smoke Studies Fogger to support USP and FDA airflow visualization in smoke studies, as well as particle size calibration of Metrology instruments.

Our Polystyrene and Silica Particle Size Standards provide the size accuracy demanded by aerosol and metrology research engineers. We provide our customers with highly accurate wafer standards, size standards and smoke study tools to achieve optimal contamination control goals. Customer satisfaction is at the heart of everything we do, and we strive to exceed expectations by offering tailored solutions and exceptional support.

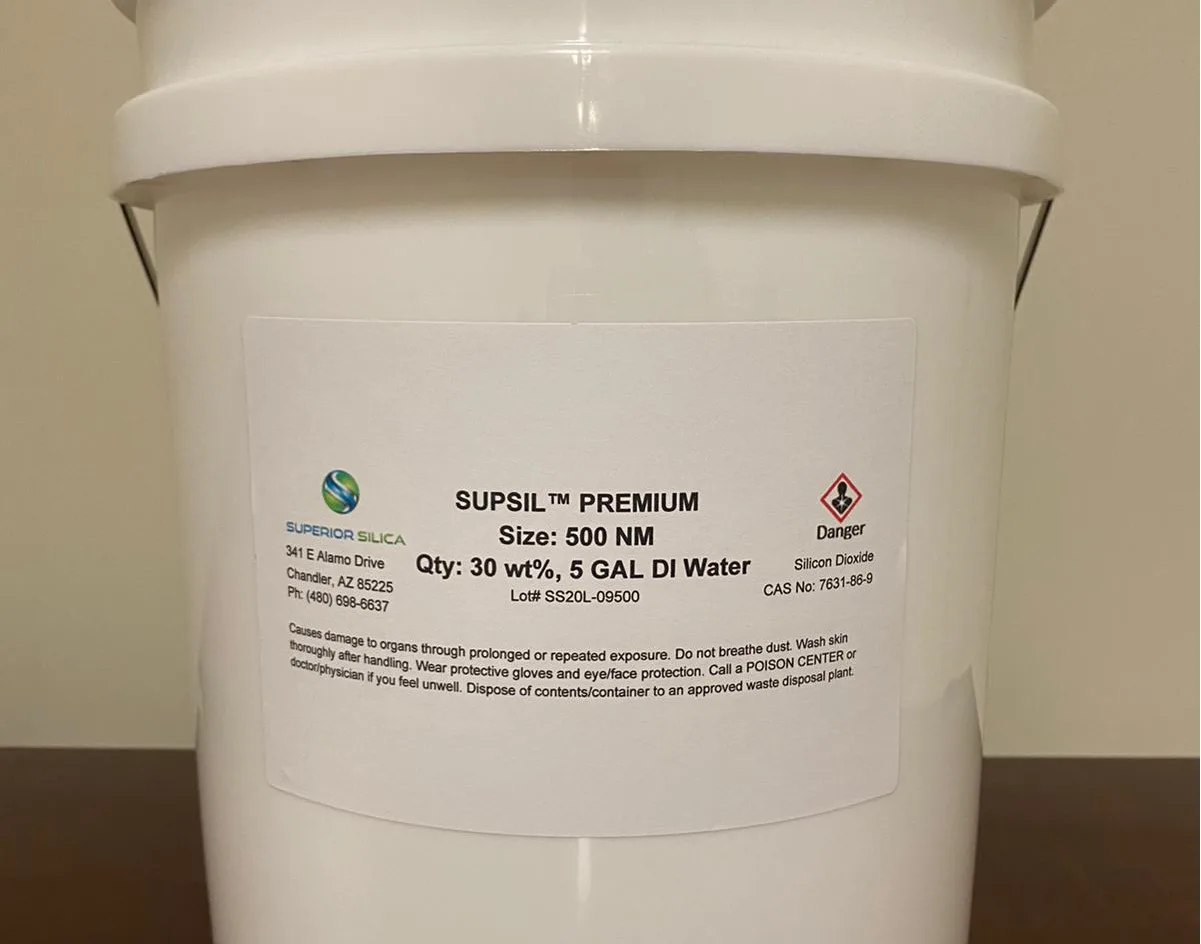

Chemical Mechanical Polish, CMP Slurry Solutions

Ultra-high purity (UHP) silica slurries for chemical mechanical (CMP) polishing with a very narrow particle size distribution at 300 nm, 500 nm and 800 nm peak sizes in 5 gallon volumes with up to 40 wt% solids. Our spherical, high purity silica enables a controlled removal rate off the silicon wafer surface to produce a very flat wafer surface. Particles are ion-stabilized for an aggregate-free solution. CMP slurries available at 300nm, 500 nm and 800 nm in 5 gallon volumes at up to 40 wt% solids.

Uncompromising Quality

Quality is the hallmark of our brand. Each product undergoes rigorous testing and quality control processes to ensure it meets the stringent requirements of our customers.

Customer Support Satisfaction

We believe that our success is measured by the satisfaction of our customers. Our dedicated support team works tirelessly to provide personalized service and solutions that address the unique needs of each client.

“Cleanroom Metrology LLC's products have significantly improved our contamination control processes. Their commitment to quality and innovation is evident in every product we use.”

Marcus Patel

Senior Process Engineer

“The precision and reliability of Cleanroom Metrology LLC’s wafer standards are unmatched. Their customer service team is always responsive and helpful, making them a trusted partner in our operations.”

Chloe Nguyen

Clean Room Manager

“We have been using Cleanroom Metrology LLC’s polystyrene latex beads for our research, and the results have been outstanding. Their products are of the highest quality, and their support team is exceptional.”

Sophie Kramer

Quality Assurance Manager

Cleanroom Metrology LLC has consistently provided us with top-notch products that meet our stringent requirements. Their dedication to customer satisfaction is commendable.”

Hannah

Research Scientist

Explore Our Product Range

Image Gallery

Discover Our Precision-Engineered Solutions

Call us to specify the Calibration Wafer Standard you need to calibrate your wafer inspection tools. We produce 300 mm, 200 mm, 150 mm, 100 mm wafer calibration standards and silica contamination wafer standards on ultra-clean silicon wafers for many Semiconductor Metrology Managers around the world. We can produce Wafer Standards using polystyrene or silica microspheres, as imaged at right. Our particle size standards and beads are used in Aerosol Science, Metrology and CMP Slurry applications around the world. Contact us today at 303-999-6837 to discuss your requirements for Wafer Calibration Standards, Smoke Studies Foggers and NIST Traceable, Particle Size Standards.