CMP slurry monitoring isn’t just another box to check in semiconductor fabs. It is the difference between a wafer that ships and a wafer that gets scrapped. Think of it like polishing glass with a mixture of fine dust and water. Most of the time, everything glides smoothly, leaving a clean, flat surface. But if even one grain of sand slips into the mix, you end up with scratches across the surface. That is essentially what happens in CMP when large particle counts slip into the slurry.

At Cleanroom Metrology, we focus on helping fabs and labs measure, monitor, and maintain standards. Whether you are working with calibration wafer standards, performing cleanroom smoke studies, using airflow visualization foggers, or testing with microspheres, the common goal is simple: consistency, control, and confidence. CMP slurry analysis is a perfect example of how detailed measurement translates directly into yield and reliability.

Why Particle Size Matters in CMP Slurries

CMP, or chemical mechanical planarization, relies on a carefully designed slurry to polish wafers down to a mirror-flat finish. These slurries are engineered suspensions of particles, usually silica, ceria, or alumina, mixed with chemicals that aid material removal.

The mean particle size of a slurry influences its removal rate. Smaller, more uniform particles mean smoother polishing and more predictable outcomes. But the danger lies in the tails of the distribution, the large particles that show up as outliers.

A few particles over 0.5 microns can leave scratches visible under inspection tools. And scratches do not just reduce surface quality, they reduce device performance and yield. If a wafer is covered with defects, the fab loses not just one wafer but potentially an entire batch worth thousands of dollars.

It is like cooking soup with fine spices. Most of the flavor comes from powders ground evenly. But if a few large chunks of unground spice sneak in, every spoonful carries the risk of biting down on something unpleasant. In IC (Integrated Circuits) fabs, those unpleasant “chunks” are the large particle counts that ruin wafers, causing millions of dollars of lost IC products, when even a few large particles of 500nm are left on a wafer.

Large Particle Counts and Yield Impact

Studies have shown a direct correlation between large particle counts and wafer scratches. For example, when specifying large particle counts as anything over 0.5 microns, scratch counts on wafers rise almost linearly with the number of large particles in the slurry.

Imagine running 100 wafers through CMP with a slurry containing a few extra microns of debris. Each wafer ends up with scratches. Multiply that across production, and the cost escalates quickly.

Some fabs assume filters are enough to control particle tails. But even after filtration, tails can persist. They can be reduced, but they rarely disappear entirely. That is why continuous monitoring matters. It is the only way to detect when particle counts drift out of control before they damage wafers.

Tools and Techniques for Particle Analysis

Particle size analysis comes in two main flavors:

Ensemble Techniques

- Dynamic Light Scattering (DLS), like the Nicomp system, gives information about the mean particle size. It is good for characterizing the main population, often in the range of ~80 to 100 nm.

- Laser Diffraction can also provide a size distribution but struggles to detect tails. It is like averaging test scores, you know the class did “okay,” but you do not notice the one student who scored zero unless you check individually.

Single Particle Optical Sizing (SPOS)

That is where SPOS shines. Systems like the AccuSizer measure particles one at a time, giving high resolution on tails. It uses sensors like:

- LE400 (0.5–400 microns, lower concentrations)

- FX (0.65–20 microns, higher concentrations)

- FX Nano (down to 0.15 microns, high sensitivity at high concentration)

Think of SPOS as a toll booth that counts every car crossing a bridge. DLS is more like standing on a hill, looking at traffic, and estimating how crowded the road is. SPOS does not estimate, it counts; and that is why fabs rely on it to catch large particle outliers.

Real-World CMP Slurry Results

Practical tests show how critical monitoring really is:

- Silica Slurries: AccuSizer proved 600 times more sensitive than laser diffraction when detecting spikes of one-micron particles. Laser diffraction did not notice the spike until particle counts rose significantly, but AccuSizer caught it immediately.

- Ceria Slurries: Mixing even 1% of a slurry with slightly larger particles into another batch caused a noticeable tail spike. At 10% the tails exploded, showing how even minor contamination can change slurry performance.

- Alumina Slurries: Measured with FX Nano, alumina slurries often appear “cleaner” but still require detailed tail monitoring to prevent rare outliers from sneaking through.

The common thread is simple: slurries can look fine when you glance at averages, but tails tell the real story.

Why Statistics Matter

Measuring only a few thousand particles is not enough to see tails. Reliable monitoring requires looking at hundreds of thousands of particles. That is why SPOS-based systems are trusted, they count enough data points to catch the rare but critical outliers.

Skipping statistical depth is like flipping a coin five times and assuming you know the odds. You do not see the real picture until you have flipped it hundreds of times.

Online vs Laboratory Monitoring

Monitoring can be done in the lab or online:

Laboratory Systems

- AccuSizer AD: Uses exponential dilution for precise particle counts.

- AccuSizer APS: Handles higher concentrations with two-stage dilution.

Great for QC of incoming slurries or stability testing.

Online Systems

- AccuSizer Mini: Installed in slurry delivery lines for continuous monitoring.

- Typically placed downstream of filters where problems often emerge.

- Fab example: Over weeks of online monitoring, one fab detected a sudden particle spike that aligned with a jump in wafer defects. The investment in monitoring paid for itself immediately by preventing repeat losses.

The beauty of online monitoring is simple. It tells you when to stop before semiconductor wafers are ruined.

Beyond CMP: Wider Applications

While CMP slurries are the most obvious use case, monitoring extends further:

- Pump performance: Detect if pumps shed particles during operation.

- Filter evaluation: Compare filters and choose the most effective for a given slurry.

- Tank withdrawals: Check if pulling from the bottom increased particle counts.

- QC on incoming batches: Ensure delivered slurry matches the expected standard.

In seasonal production peaks, (during summer when fabs often run hotter and harder) monitoring can prevent filter overload or slurry instability from slipping by unnoticed.

How Cleanroom Metrology Products Support CMP Monitoring

At Cleanroom Metrology, we do not just discuss these issues in theory. We provide tools and standards to help fabs act with confidence:

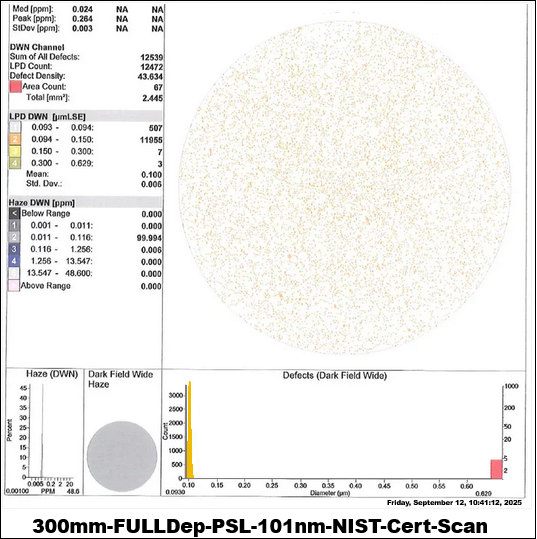

- Calibration Wafer Standards: For validating that particle size instruments measure accurately.

- Silica & Polystyrene Microspheres: Used as particle size standards and in slurry spiking experiments to test system sensitivity.

- Airflow Visualization Foggers & Smoke Studies: Ensure cleanroom environments do not introduce airborne particles that can settle into slurries or wafer surfaces.

By integrating monitoring with trusted reference materials, fabs close the loop between measurement and control.

FAQs

Are these instruments too sensitive?

Sensitivity is the point. Detecting tails early prevents entire wafer lots from being scrapped.

But we already filter our slurries.

Filters help, but they do not catch everything. Monitoring confirms performance in real time.

Online monitoring is too costly.

What is more expensive, a monitoring system or losing a batch worth millions of dollars? Customers who adopted online particle monitoring saw ROI with the very first avoided excursion.

Conclusion

CMP slurry monitoring is not optional. It is the shield that protects wafer yield against invisible threats. Large particle counts are like tiny landmines in the slurry, rare but destructive when they strike. By combining statistical strength, sensitive instruments, and trusted standards, fabs secure consistency across production.

At Cleanroom Metrology, we support that mission with calibration wafers, microspheres, smoke studies, and foggers. These are tools designed for one purpose: giving fabs the confidence that what they cannot see will not cost them.