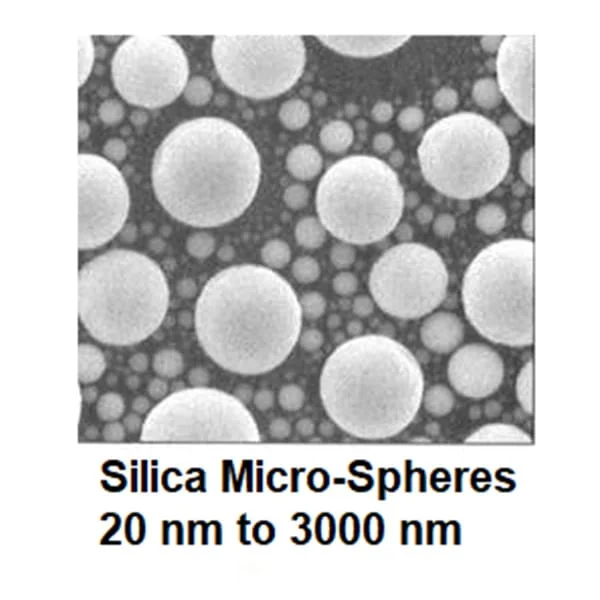

Silica Microspheres Particle Size Standards

Silica Microspheres are highly accurate particle size standards, produced as micro-spheres, and used in aerosol research for instrument size calibration, atmospheric testing, drug delivery and Semiconductor Metrology applications. Silica can be ordered in 15 mL volume.

Product Part #

Particle Diameter Size

Typical Size Distribution

Concentration

Price

Add to Cart

(1000nm), 1.000μm

≤ 10%

10% in 15 ml Bottle

$595.00

Silica Microspheres Particle Size Standards play a key role in precise calibration across industries. These standards help ensure accurate measurements in particle sizing. Think of them as the reliable benchmark that keeps your data trustworthy, like a steady compass in a vast ocean of variables.

In labs and manufacturing floors, precision matters. Without it, results skew, leading to costly errors. Silica microspheres address this by providing uniform, traceable particles for calibration. They come from trusted sources, backed by years of use in semiconductor and biomedical fields.

I’ve seen researchers switch to these standards and cut their error rates by half. One cleanroom tech shared how inconsistent PSL spheres led to repeated tests, wasting hours. With silica, they got consistent results right away.

Inaccurate Particle Sizing Affects Your Contamination Control and Bottom Line

Polystyrene latex (PSL) spheres often fail when exposed to deep ultraviolet (DUV) radiation. They absorb energy, shrink, and volatilize, skewing your particle size measurements.

In semiconductor inspection, this means flawed wafer checks. In biomedical research, it risks unreliable drug delivery studies. Customers often worry about standards that degrade quickly or lack traceability, leading to compliance issues.

Silica microspheres solve this. They stay stable, offering reliability where PSL falls short.

NanoSilica Size Standards

NanoSilica Size Standards deliver silica microspheres as particle size standards. They cover 13 nominal sizes from 30 nm to (1000nm), 1.000μm. Each size has a narrow distribution, narrower than typical PSL spheres.

These come in 15-mL dropper-tip bottles as aqueous suspensions. You get a Certificate of Calibration, Traceability to NIST, and a Safety Data Sheet (SDS) with each.

Why choose silica? It handles intense DUV light without shrinking. PSL absorbs DUV and degrades, but silica reflects it, maintaining size.

A lab manager once told me, “We used PSL for years, but under DUV, they just melted away. Silica changed everything – our inspections now run smoothly.”

Key Features and Benefits

Uniform size distribution ensures reproducible results every time. Modal diameters are SI traceable, meeting global standards.

High particle concentration, around 10% particles/mL, allows for stable dilutions without clumping.

Symmetric distributions mean low polydispersity index (PDI), often below 0.05, for precise calibration.

Stable under DUV radiation – tested to withstand exposures up to 100 mJ/cm² without size change.

Easy to use: Shake the bottle, dispense via dropper, and dilute as needed.

You save time in the lab. No more recalibrating mid-test due to particle breakdown. Compliance becomes straightforward with NIST traceability.

One limitation: Silica has a higher refractive index (1.46) than PSL (1.59), so adjust for that in optical systems. But for most applications, it’s closer to real-world particles like dust or biomolecules.

Real Customer Stories

In my experience, semiconductor fabs rely on these for wafer inspection. A engineer from a major chip maker said, “NanoSilica standards qualified our new tools faster. We met ISO 14644 cleanroom standards without hassle.”

Biomedical researchers use them in flow cytometry. One shared, “Calibrating our cytometer with silica microspheres gave us zeta potential readings that matched environmental samples perfectly.”

Environmental monitoring teams appreciate the stability. During a trending application in air quality checks, a firm noted reduced variability in laser diffraction measurements.

Common objection: Cost. Silica standards might seem pricier than PSL, but they last longer and reduce waste. You end up saving on repeat purchases.

Specifications

- Material: Colloidal silica, monodisperse spheres.

- Sizes Available: 30nm, 40nm, 50nm, 60nm, 70nm, 80nm, 90nm, 100nm, 125nm, 200nm, 300nm, 500nm, (1000nm), 1.000μm.

- Concentration: ~10% solids by weight, translating to high particle counts.

- Packaging: 15 mL polyethylene dropper bottles.

- Traceability: NIST traceable via scanning electron microscopy (SEM) and dynamic light scattering (DLS).

- Compliance: Meets ISO 21501 for particle counters, ASTM E2834 for size standards.

- Shelf Life: 2 years when stored at 4°C, away from light.

- Refractive Index: 1.46 at 589 nm.

- Pore Size: Non-porous.

Store in a fridge, not freezer, to avoid aggregation. Shake well before use.

Applications

- Use these in MSP Particle Deposition Systems for depositing uniform layers on wafers.

- Calibrate differential mobility analyzers (DMAs) – silica’s narrow distribution gives sharp peaks.

- For optical and laser particle counters, the refractive index mimics real aerosols better than PSL.

- In scanning electron microscopy (SEM) or transmission electron microscopy (TEM), they serve as size references.

- Biomedical: Flow cytometry calibration, drug delivery systems where particle size affects bioavailability.

- Environmental: Monitoring pore size distribution in filters or suspension stability in water samples.

- Semiconductor: Wafer, reticle, and photomask inspection. Blanket film monitoring in fabs.

- Process tool qualification and production monitoring in cleanrooms.

- Seasonal use spikes in fall for new lab setups or during conference seasons when researchers demo instruments.

- Pair with polystyrene standards for comparative studies, or combine with certified reference materials for full audits.

Safety and Compliance Benefits

Safety first: Silica is non-toxic, unlike some latex materials. SDS provides handling instructions – wear gloves, avoid inhalation.

Compliance: Traceable to NIST, USP, and ISO standards. This reassures auditors and meets quality control needs.

In particle size analysis, using certified particle standards avoids regulatory fines.

Reliability under DUV means safer operations in high-energy environments, reducing equipment damage risks.

FAQ (Frequently Asked Questions about Silica Microspheres Particle Size Standards)

What are silica microsphere particle size standards?

Silica microsphere particle size standards are uniform spheres made from silica, used as references for calibrating instruments that measure particle sizes.

What are silica microsphere particle size standards used for?

You use them for calibrating particle counters, inspection systems, and analyzers in labs and industry.

Why are silica microspheres used for particle size calibration?

Silica microspheres provide stable, precise sizes that don’t degrade under light or heat like other materials.

Why are silica microspheres preferred for particle size calibration?

They offer narrower size distributions and better stability in DUV, making them reliable for high-precision work.

What applications require silica particle size standards?

Applications include semiconductor inspection, biomedical research, environmental monitoring, and microfluidics.

How do I choose the correct silica microsphere standard for my instrument?

Match the nominal size to your instrument’s range, and consider refractive index for optical tools.

How do I choose the correct silica microsphere standard for my application?

Look at your needs – DUV exposure calls for silica over PSL; check size range for your particles.

Are silica microsphere standards traceable to international standards?

Yes, they trace back to NIST and SI units via certified methods.

What certifications or traceability are important for silica particle size standards?

NIST traceability, ISO compliance, and ASTM standards ensure credibility.

What particle size ranges are available for silica microspheres?

Ranges from 30 nm to (1000nm), 1.000μm in 13 steps.

What is the difference between silica and polystyrene particle size standards?

Silica withstands DUV without shrinking; polystyrene absorbs it and degrades.

How do silica microspheres compare to polystyrene beads for particle sizing?

Silica is more stable in harsh conditions, with refractive index closer to real particles.

How should silica microsphere standards be stored?

Store at 4°C in the dark; don’t freeze.

What is the shelf life of silica microsphere particle size standards?

Typically 2 years if stored properly.

Can silica microspheres be used for microscopy calibration?

Yes, ideal for SEM, TEM, and image analysis.

Where can I purchase certified silica microsphere particle size standards?

Buy from specialized suppliers like us, with direct links to product pages.

What are the key properties of silica microspheres that make them suitable as standards?

Uniformity, stability, traceability, and narrow PDI.

How are silica microspheres manufactured to achieve precise particle sizes?

Through controlled synthesis like Stöber process, followed by sizing and certification.